Low MOQ for Large Diameter Spiral Welded Carbon Steel Pipe

Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction for Low MOQ for Large Diameter Spiral Welded Carbon Steel Pipe, For additional information and facts, please speak to us as quickly as possible!

Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction for China Spiral Welded Pipe and Spiral Carbon Steel Pipe, Now the competition in this field is very fierce; but we are going to still provide best quality, reasonable price and most considerate service in an endeavor to achieve win-win goal. “Change for the better!” is our slogan, which means “A better world is before us, so let’s enjoy it!” Change for the better! Are you ready?

Product Description

The crack resistance of spiral welded pipe is better than that of straight welded pipe. The spiral angle of spiral welded pipe is generally 50-75 degrees, so the synthetic stress of spiral welded joint is 60-85% of the main stress of straight welded pipe. Under the same working pressure, the wall thickness of spiral welded pipe with the same pipe diameter is smaller than that of straight welded pipe. The size is accurate. Generally, the diameter tolerance is not more than 0.12%, the deflection is less than 1 / 2000, and the ovality is less than 1%. Generally, the sizing and straightening process can be omitted.

Product Parameter

| Standerd | GB ASTM API-5L JIS DIN |

| Steel pipe grade | Q235A,Q235B、0Cr13、1Cr17、00Cr19Ni11、1Cr18Ni9、0Cr18Ni11Nb、16Mn、20#、Q345、L245、L290、X42、X46、X70、X80。 |

| Lengh | 6-35m |

| Outer Diameter | 89-2450mm |

| wall thickness | 0.5-25.4mm |

| Processing Service | according to the customer’s demand |

| Packaging Details | Bare packing/wooden case /waterproof cloth |

| Terms of Payment | T/T L/C at sight |

| 20 feet container contains dimension | Length under 6000mm/25T |

| 40 feet container contains dimension | Length under 12000mm/27T |

| Min order | 1 Ton |

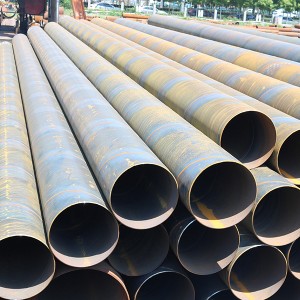

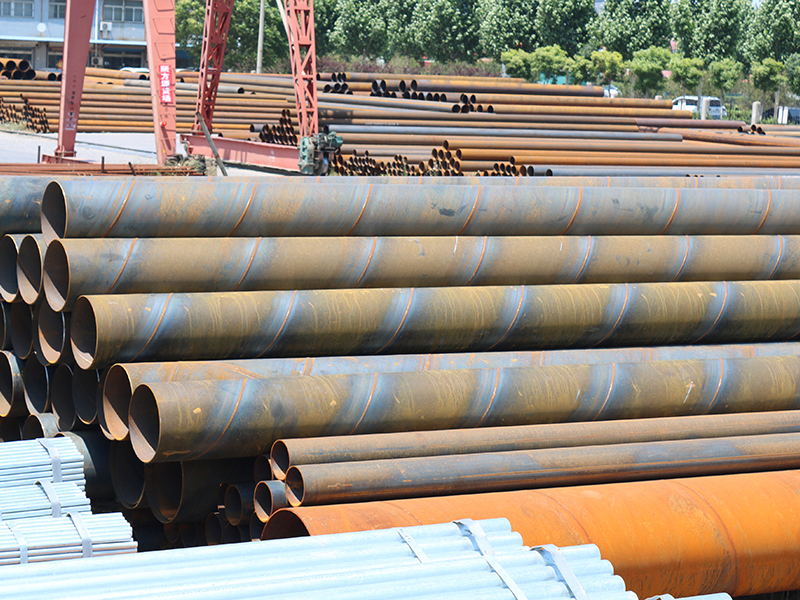

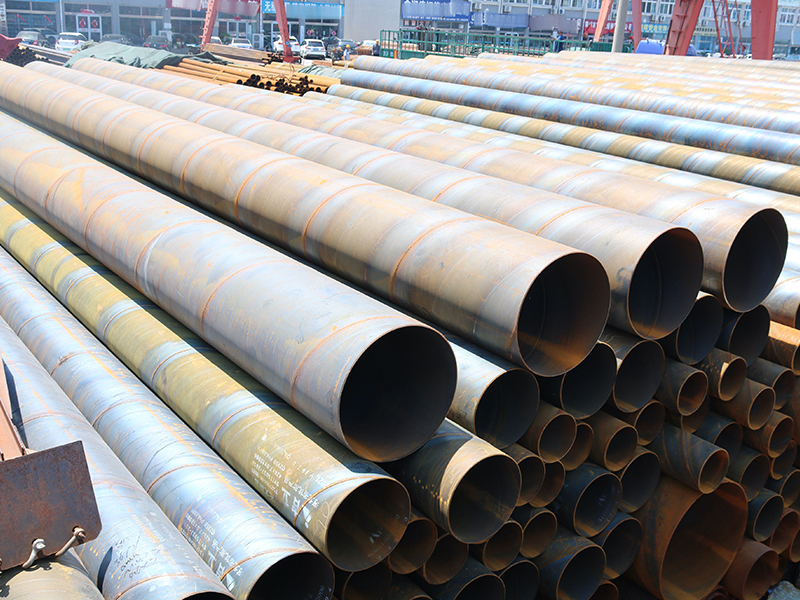

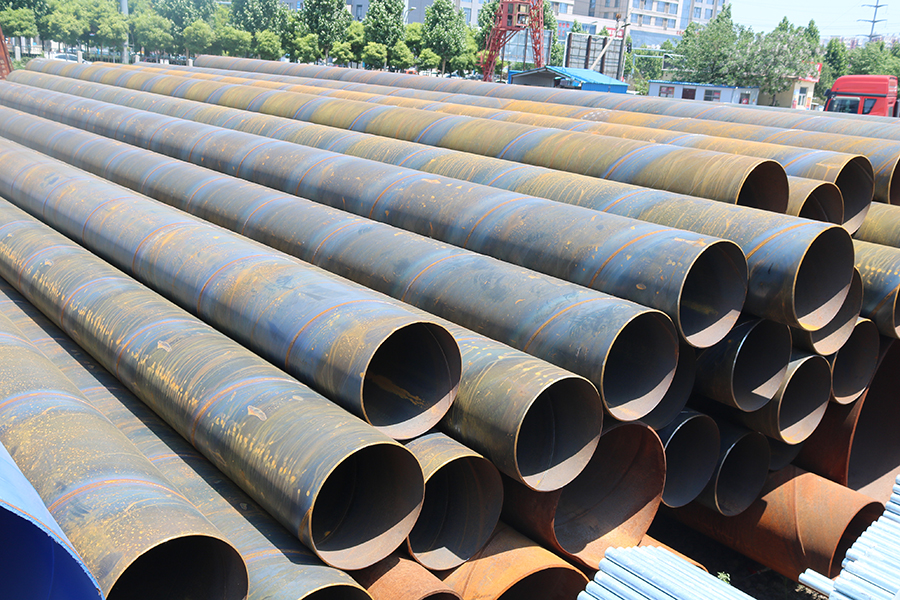

Product Show

Product Application

Spiral welded pipe is mainly used in water engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation and urban construction in China. Used for liquid transportation: water supply and drainage. For gas transmission: gas, steam, liquefied petroleum gas. Used for structure: piling pipe and bridge; Pipes for wharf, road, building structure, etc.

Advantages

Our company has a large number of inventory, can meet your needs in time.

provide relevant information in time according to the customer’s demand to ensure the quantity and quality of products.

Relying on the country’s largest steel market, one-stop with all the products you need to save costs for you.

Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction for Low MOQ for Large Diameter Spiral Welded Carbon Steel Pipe, For additional information and facts, please speak to us as quickly as possible!

Low MOQ for China Spiral Welded Pipe and Spiral Carbon Steel Pipe, Now the competition in this field is very fierce; but we are going to still provide best quality, reasonable price and most considerate service in an endeavor to achieve win-win goal. “Change for the better!” is our slogan, which means “A better world is before us, so let’s enjoy it!” Change for the better! Are you ready?

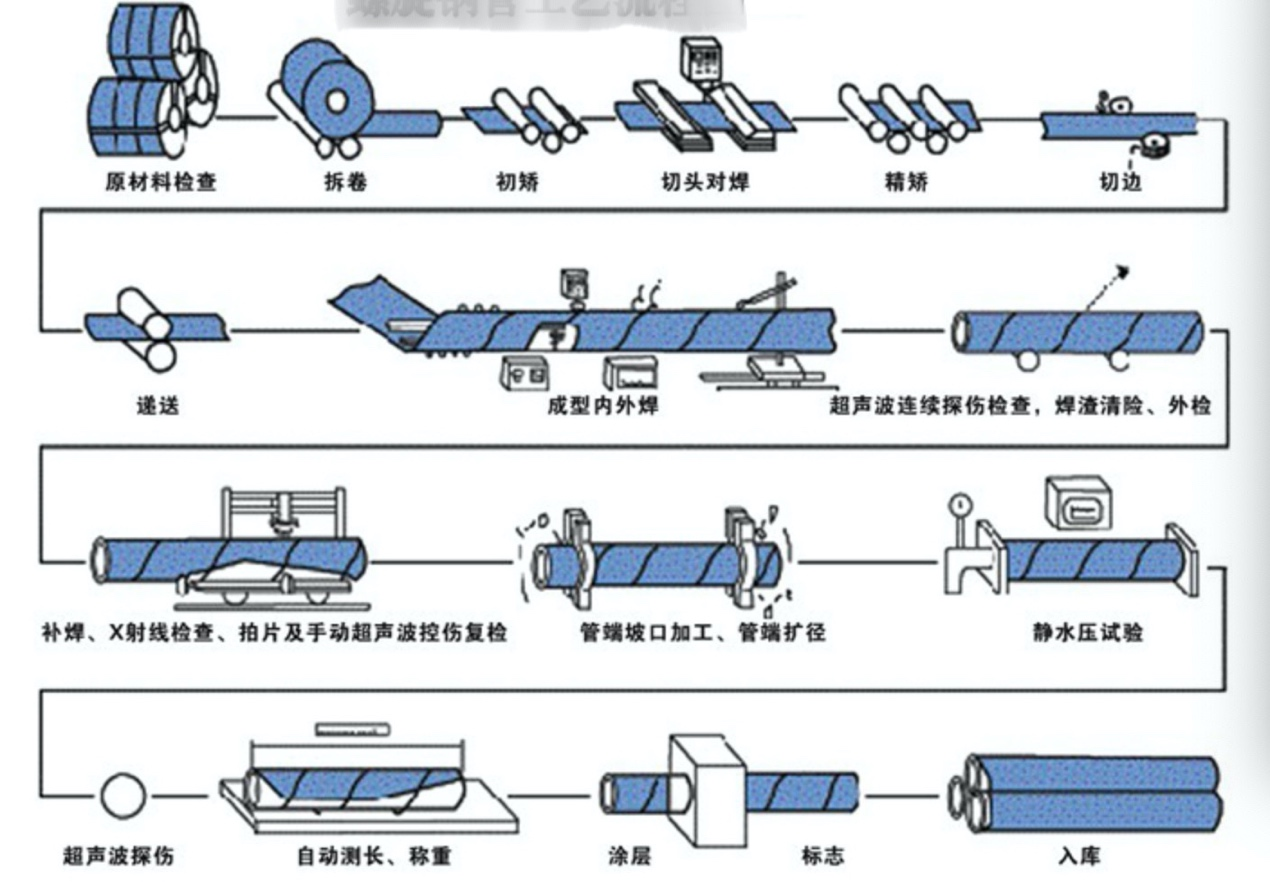

Production Process